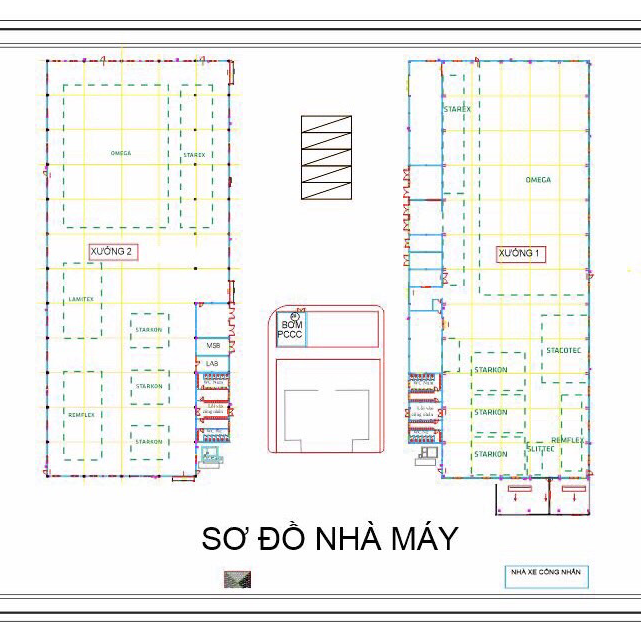

1-Extrusion Lines

All have several things in common: advanced technology, an excellent price-performance ratio, clarity and ease of operation, proven technology based on years of experience, simple maintenance and high production speeds – even with the new material-saving, extremely thin tapes.